Products

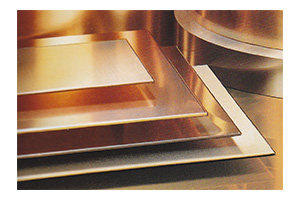

Copper Tubes

AREAS OF APPLICATION:

REFRIGERATION, HEATING, GAS, DRINKING WATER, FUEL, and MEDICAL GAS INSTALLATIONS

TECHNICAL PROPERTIES

|

STANDARDS | |

|---|---|

|

EN |

Cu-DHP / CW024A |

|

ASTM |

C 12200 |

|

DIN |

SF-Cu |

|

TECTUBE-KME |

Cu-DHP |

|

AFNOR |

Cu-b1 |

ALLOY

DEOXIDIZED COPPER PHOSPHORUS

|

Cu (COPPER) |

P (PHOSPHOR) |

|

min. % 99,90 |

% 0,015 - 0,040 |

PHYSICAL PROPERTIES:

|

DENSITY(g/cm2) |

THERMAL CONDUCTIVITY at 20°C(W/m°K) |

ELECTRICAL CONDUCTIVITY |

COEFFICIENT OF THERMAL EXPANSION (10-6/K) |

MELTING POINT (°C) | |

|---|---|---|---|---|---|

|

(m/Ωmm2) |

IACS | ||||

|

8,94 |

340 |

min. 40 |

% 79 |

17,6 |

1083 |

MECHANICAL PROPERTIES:

|

TEMPER |

EN 1057 CLASSIFICATION |

TENSILE STRENGTH (min.) |

ELONGATION %5 (min.) |

HARDNESS (HV5) |

|---|---|---|---|---|

|

SOFT (ANNEALED) |

R220 |

220/mm2 |

40 |

40 - 70 |

|

HALF HARD |

R250 |

250/mm2 |

30 |

75 - 100 |

|

HARD |

R290 |

290/mm2 |

3 |

min. 100 |

STANDARDS OF COPPER TUBES ACCORDING TO AREAS OF APPLICATIONS:

|

AREAS OF APPLICATION |

STANDARDS |

|

PLUMBING, HEATING and GAS INSTALLATIONS |

EN 1057, ASTM B88, EN BS 2871 |

|

AIR-CONDITIONER and REFRIGERATION INSTALLATIONS |

EN 12735-1, EN 12735-2, ASTM B280, ASTM B68 |

|

MEDICAL GAS INSTALLATIONS |

EN 13348 |

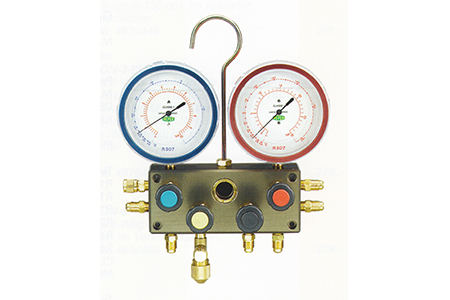

Fittings

AREAS OF APPLICATION

REFRIGERATION, HEATING, GAS, DRINKING WATER, FUEL & MEDICAL GAS INSTALLATIONS

TECHNICAL PROPERTIES:

|

MATERIAL |

STANDARDS |

ALLOY |

|---|---|---|

|

COPPER |

EN 1254 |

Cu-DHP (CW024A) |

|

BRASS |

EN 1254 |

CuZn39Pb2 |

PRESSURE and TEMPERATURE VALUES:

|

SOLDER or BRAZING MATERIAL |

FLUID TEMPERATURE (°C) |

TUBE DIAMETERS (mm) and WORKING PRESSURE (BAR) | |||

|---|---|---|---|---|---|

|

6 - 34 |

35 - 54 |

66 - 108 | |||

|

SOFT SOLDER |

Sn97-Cu3 |

30 |

25 |

25 |

16 |

|

65 |

25 |

16 |

16 |

||

|

110 |

16 |

10 |

10 |

||

|

HARD SOLDER(BRAZING) |

L - CuP6 L - Ag5P %30 SILVER BRAZING WIRES %40 SILVER BRAZING WIRES |

30 |

25 |

25 |

16 |

|

65 |

25 |

16 |

16 |

||

|

110 |

16 |

10 |

10 |

||

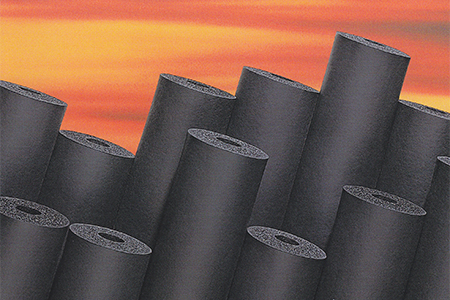

Rubber Insulation

TECHNICAL PROPERTIES:

| PROPERTIES | VALUE | TEST METHOD |

|---|---|---|

| DENSITY | 55 - 90 kg/m3 | ASTM D 1667 |

| TEMPERATURE RANGE | -50°C ÷ +105°C | |

| THERMAL CONDUCTIVITY | -20°C'de λ ≤ 0.030 W/m°C | ASTM C 534-02 |

| WATER ABSORPTION | 0.2% (hacmen) max. | ASTM C 534-02 |

| WATER VAPOUR DIFFUSION | μ ≥ 7000 | DIN 52615 |

| CFC | NONE | SFS 4190 CLASS 1 |

| RESISTANCE TO OIL | EXCELLENT | |

| OZONE RESISTANCE | NO CRACKING | ASTM D 1171 |

| U.V. RESISTANCE | NO CRACKING | ASTM G 154-00 |

| FIRE RATING | CLASS "0" | BS 476 Part 6 |